How Axiom's customers resolve 70% of predictive anomalies within 45 days

If you run energy, maintenance, compliance, or operations for a grocery chain or cold-storage company, you already have a lot in place: connected refrigeration controllers, hundreds of on-site sensors, an alarm monitoring provider, alarm monitoring and triage workflows, a work-order management system, a refrigerant tracking system, and a network of preferred refrigeration service vendors. The problem isn’t a lack of data or tools. It’s the gap between data → insight → action.

Most platforms provide data visibility to “empower your employees to make better decisions”. The problem: who has the time or expertise for that? Many platforms also provide “actionable insights.” In practice, that’s a polite way to say another to-do list—and you already have a task list that is a mile long. Axiom takes a different approach: we sit inside your existing stack and help your team focus on the single most important thing to do next, then we stay with you until the root cause of the issue is actually resolved.

Fully-Remote Deployment. Fast Time to Value.

Every site already produces a treasure trove of live data. Historically, most of it never leaves the facility and gets overwritten in as little as 72 hours. Axiom securely streams a few hundred key points from each site to the cloud, cleans, labels, and normalizes them so they’re useful anywhere, on any device—without new hardware, sensors, or on-site installs. That’s how we scale across thousands of locations quickly.

But we don’t stop at data plumbing, because your team doesn’t have the time (or desire) to review thousands of live data streams every day.

From Noise to Signal: Only 2-3 High-Value Anomalies per Year at Each Site

Across 500 retail grocery facilities, our AI paired with a US-based team of veteran refrigeration specialists surfaces roughly 100 high-value anomalies per month - predictive opportunities tied to early leak detection, predictive maintenance, or energy efficiency. That’s only 1 anomaly for every 5 sites each month. Each anomaly is packaged like a super-useful work order:

What it is (in plain English) and likely root cause

Exact location in the store

A concise graph with the right timestamps so humans can see it

Step-by-step actions to diagnose and fix it

Urgency and the financial cost of delay (so the business case is obvious)

And yet, even a stack of 100 excellent anomalies can stall. That’s where Axiom’s biggest differentiator kicks in.

No Rip-and-Replace. Seamless Integration with Existing Systems and Workflows.

404a rack in the machine room at a grocery store

Every company is different. Some retail grocery chains rely on store managers to monitor alarms, while others use 3rd-party call centers. Some have technicians on staff, while others outsource all maintenance to local contractors. We have seen it all - these are just a few examples of how companies do things differently.

Our customers have made it crystal clear: they do NOT want to rip-and-replace their existing sensors, controllers, alarm monitoring solutions, work order management systems (CMMS), maintenance vendor networks, or refrigerant tracking systems (RTS). Instead, our customers have asked us to build integrations so that Axiom’s proactive refrigeration management strategies can be seamlessly integrated with these existing systems and workflows. Axiom enables our customers to avoid disruptive change-management initiatives via a robust library of integrations with existing systems. For example, Axiom can integrate with all of the leading refrigeration controllers on the US market today and major CMMS platforms.

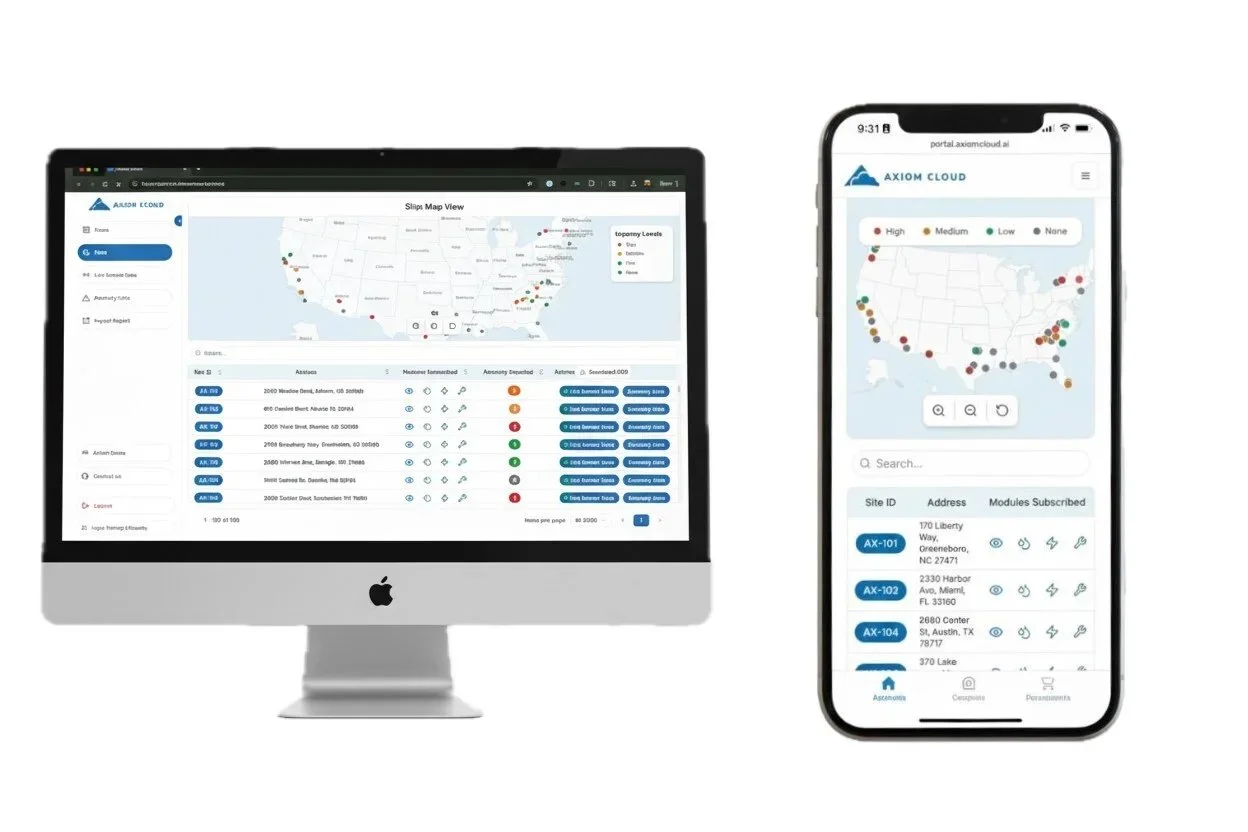

In addition, customers begin receiving value from Axiom in the first month of operation because Axiom can reach the right stakeholders at the right time via existing channels. For example: anomalies can be presented via email, as “work order requests” in their CMMS’s existing work order approval process, in Axiom’s modern Customer Web Portal, or during bi-weekly calls with maintenance and energy managers.

The bottom line: we meet our customers where they are today, rather than asking them to make painful changes to their infrastructure or processes. This strategy has driven incredible results for our customers in our first five years - learn more about our “not-so-secret sauce” below.

From 200,000 live data streams to 1 high-value service call

Growth is obviously Axiom’s most important metric. “Timely Resolution Rate” of anomalies sent is our 2nd most important metric. Basically, this measures the percentage of anomalies sent to customers that were fully resolved within 45 days. We are proud to share that Axiom’s customers have consistently achieved a 70% “timely anomaly resolution rate” on average throughout 2025 - and rising!

This is the strategy we have developed and refined to help our customers succeed month after month, by the numbers, for a customer that operates 500 grocery stores:

Triage based on your priorities. From the ~100 monthly anomalies, we work with you to triage out 20-30 based on real-world priorities: a store that’s closing, a remodel, a CFO directive to chase energy first, or a CEO push to tighten leak compliance. We align to your constraints so the list reflects what truly matters now.

Resolve what you can remotely. It is usually possible for a maintenance or energy manager to resolve ~10 issues per month remotely in a few hours at a computer (often related to setpoint changes, algorithm updates, or programming errors). That immediately shrinks the list of anomalies that require expensive onsite service calls.

Batch the rest into efficient service calls, then dispatch the single-most important one. The remaining anomalies are prioritized and batched into ~15 in-person service calls. We determine which store should be visited first. Then, we specify the technician’s skill level and materials needed for each service call (e.g., Level 5 technician with 404A on the truck), so the technician knows what they will encounter BEFORE they arrive onsite. The technician is then well-prepared to address multiple issues during a single service call visit. Expensive field time is focused where it produces the highest ROI.

Clearly specify the location, root cause, and suggested actions to diagnose/repair each issue so that early-career technicians have a higher chance of succeeding the first time. Data alone isn’t enough to improve outcomes - Axiom uses the data to provide specific instructions that help technicians do their jobs better. The era of sending out a rookie and hoping they can find a relevant troubleshooting youtube video is over. With Axiom, customers see measurable increases in first-time fix rates and fewer technician “call-backs.” Helping early-career technicians succeed and work efficiently is especially impactful because of the shortage of qualified technicians, which is getting worse every year.

Validate outcomes automatically. Using live data, we confirm when the root cause of an issue has been resolved, if an issue has received a “band-aid solution”, and which issues remain open. We do NOT rely on technicians’ notes or invoices for this. Axiom’s approach enables our customers to more tightly manage contractors, so they don’t have to pay for 2-3 “call-backs” to resolve the same issue (instead, customers can demand zero-cost call-backs from contractors if issues weren’t properly addressed during the initial service call). Every month, that closed loop lets us streamline PMs, identify vendor trends, and quantify benefits (kWh, service calls, CO2e, $$, etc.).

The Flywheel: Less Downtime, Fewer Alarms, Lower Costs

A typical grocery chain with 500 stores might experience 50,000 reactive alarms per month (with a timely resolution rate <5%). When Axiom adds ~100 high-value anomalies into your existing alarm triage funnel (with a timely resolution rate of 70%), that enables teams to begin working proactively to avoid a flood of reactive alarms in the future. Then, Axiom works closely in partnership with you until the root cause of the issue is actually resolved. As the right work gets done, the total reactive alarm load drops in subsequent months. That improvement compounds—creating a refrigeration flywheel that makes every month easier than the last.

Axiom refrigeration specialist inspecting an ammonia chiller at a cold storage warehouse

Why This Works for Enterprise Operators

No rip-and-replace. We integrate with your controllers, alarms, work orders, CMMS, RTS, and contractor network.

AI + human expertise. Analytics plus a seasoned US-based refrigeration team ensures the signal is real—and actionable. And, expert support is available anytime upon request.

The ONE most important thing. Your team can focus on the single item that moves the needle today, not a 100-item backlog.

Measured business outcomes. Live-data validation quantifies results for internal reporting: service calls avoided, kWh saved, CO₂e avoided, and bottom-line $ impact.

The Bottom Line

If your organization is drowning in alarms, data, or “actionable insights” (the worst of all) the missing piece isn’t another dashboard. It’s a partner that uses data to help you solve real problems - within your existing stack - and proves it with live data. Axiom is already doing this for many US retail grocery chains and cold storage companies at scale. We cut the noise, drive the critical last mile of action, and help you turn reactive firefighting into a proactive refrigeration flywheel.

Want to see how Axiom can help your team manage refrigeration more proactively? Send us 10 stores to start. We’ll help you address ~3 of the most impactful opportunities you can take to lower your refrigeration energy bills, maintenance costs, or refrigerant leak rates - and prove the impact in 45 days.